When you think of ordering your new signs, the hole pattern might not be top of mind. The hole pattern is

the location of holes in your sign, and is something that you need to consider each time you order.

We've put together this web page to help explain the importance of the hole patterns, why patterns are

different for frames and posts, how holes are measured, and how to order custom holes if needed.

THE IMPORTANCE OF HOLE PATTERNS

Holes are typically drilled/punched into your signs so that they can be assembled with your frames or

hung from your posts. In order for you to install your signs to your frames or posts properly, the hole

patterns must match.

Unfortunately there is no “universal” hole pattern used by all sign suppliers. Each of the major

suppliers have developed their own hole patterns. If you are using sign panels from one supplier, and

frames or posts from another supplier, then there is the chance that the holes in your sign will not

match those in your posts and frames. This will prevent you from being able to display your signs

properly.

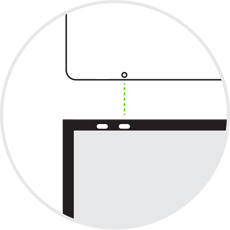

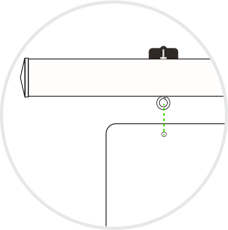

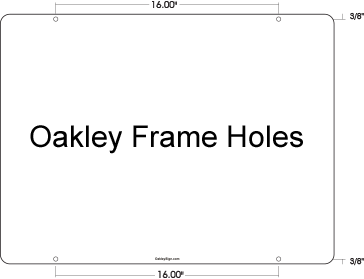

Oakley Sign Panel

Oakley Frame

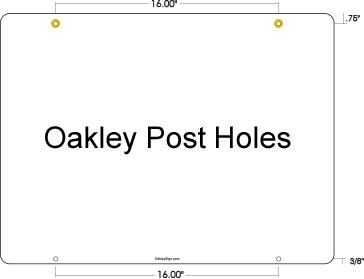

Oakley Sign Panel

Competitor Frame

Hole patterns also differ based on how you use your signs. The hole patterns used when installing your

panels into angle iron or round rod frames can differ from the hole patterns used to hang your signs

from posts.

WHAT HOLE PATTERN IS RIGHT FOR YOU?

If you purchase your sign panels as well as your frames or posts from Oakley Signs ∓ Graphics, then

you will just need to specify how your panels will be used, and we'll know which hole pattern to use for

your signs.

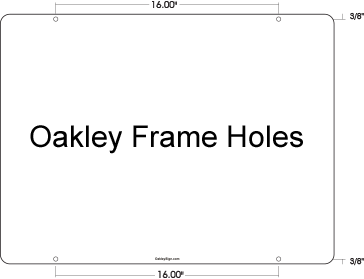

The first option is our "Oakley Frame" pattern , used when assembling your panels with any of our angle

iron or round rod frames.

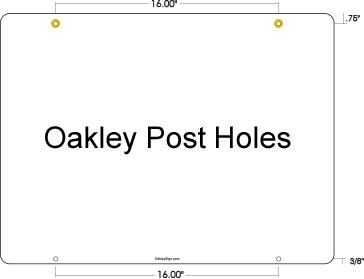

The second option is our "Oakley Post" pattern, used when hanging your panels from any of our posts or

crossarm stakes.

It is also possible to request “no holes” when the panel can slide into a frame, and does not need to be

bolted in.

If you order signs to fit frames or posts from a different supplier, you will need to supply us with that

hole pattern. If you do not know the specifics of the hole pattern, you will need to measure the pattern

on the frames or posts you intend to use. If your panels are being installed by a professional sign

installer, simply ask the installation company to provide the hole pattern they prefer. All measurements

must be provided to Oakley in U.S. standard sizes and ⅛” increments.

HOW TO MEASURE HOLES?

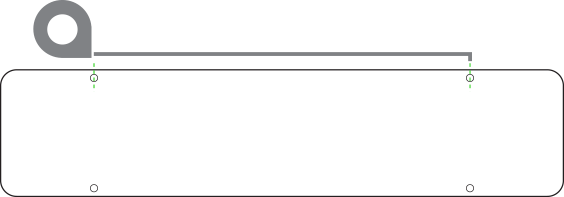

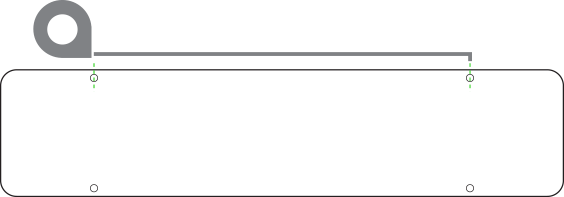

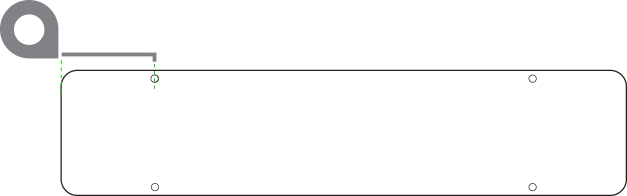

Start by measuring the top holes. Measure the distance from the center of the first hole to the center of

the second hole. If there are more than 2 holes on the top, then take this measurement for the 2 holes

closest to the center of your sign. Make a note of this distance in inches as “total inches on center.”

For instance, if the distance between the center of the 2 holes is 19 inches, then make your note as

“Inside holes are 19 inches on center”.

Measure the inside holes of your sign

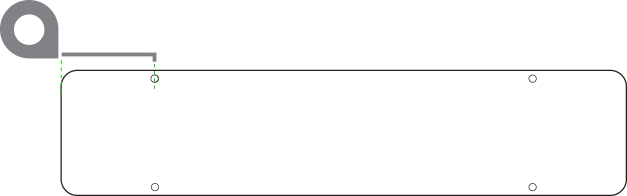

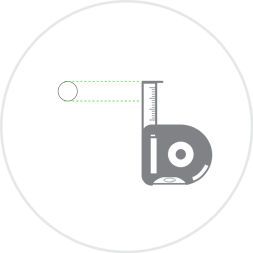

If there are more than 2 holes on the top of the sign, then measure the next set of holes by measuring

the distance from the outside edge of the sign, to the center of the outside holes. Make your note for

these outside holes as “total distance from side edge.” So if the distance from the outside edge to the

center of the outside hole is 3 inches, then you make your note as “Outside holes are 3 inches from side

edge.”

Measure the outside holes of your sign if applicable

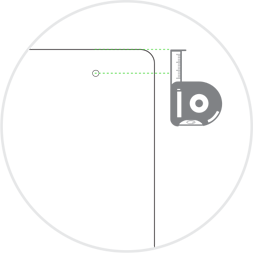

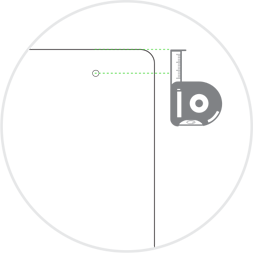

Next, you need to measure the distance from the top edge of your sign to the center of the top holes.

This measurement will be noted as “total distance from top edge.” So if the distance from the top edge

to the center of the top holes is 3/8 inch, then you make your note as “Top holes are 3/8 inches from

top edge.”

Measure the distance from the top edge of your sign

to the center of the top holes

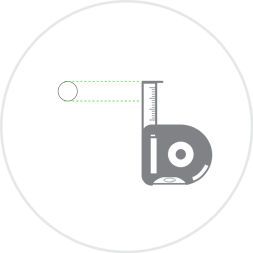

Finally, we will need to know the diameter of your holes. By default we include our Standard 5/16”

diameter holes for all custom hole patterns. We can also provide ⅛” and ½” diameter holes if requested.

Measure the diameter of your holes

You will now repeat this exact process to measure the holes in the bottom of your sign. Once you have

done this, you can supply this complete list of information with your order and we will be able produce

your signs with this custom hole pattern.

If you plan to use your signs as “hanging signs” from posts or are supplying your signs to a professional

sign installer, you will want to request that grommets be installed in the top holes to give them added

protection from tearing and bending. Please note: Due to the additional labor involved with custom holes

and extra grommets, additional charges may apply.

THE OAKLEY HOLE PATTERNS

The Oakley Signs & Graphics hole patterns vary based on the width of the signs, the sign material,

how the sign will be used, and in some cases they are unique to specific products. You can view a

complete chart of our hole patterns at www.oakleysign.com/sign-hole-pattern/, which outlines full details of our hole

patterns including those used with our specialty products.

If you would like further information or additional advice on hole patterns please contact us at

800-373-5330 and a member of our customer service team will be happy to help you.